Fumigating a 6.5 GM Turbo Diesel

Fumigating a 6.5 GM Turbo Diesel

Read https://bigbay4bestbuys.com/fumigating-diesel-safely fully and then -- things you will need are:

1. A STOCK - un modified GM 6.5 Diesel in perfect - "purring" running condition

2. High quality fuel - or aditive to bring the quality up to better than pump Cetane => see https://bigbay4bestbuys.com/cetane_booster

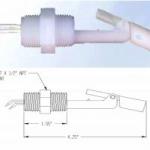

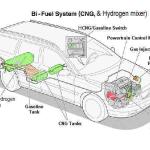

3. A fumigating mixer and metering device as part of a gaseous fueling system of CNG or Hydrogen and CNG called "HCNG - or commercially known as Hythane => see https://bigbay4bestbuys.com/content/hcng-mixer-diesels-cng-and-gasoline…

4. An adjustable line pressure solenoid (also called a "force motor" by some) in the transmission so you can turn up the line pressure See for example https://www.ebay.com/sch/i.html?_odkw=50058&_osacat=0&_from=R40&_trksid…; (we have no need to sell these)

5. A postivie displacement Sure-Cure lift pump. See => https://bigbay4bestbuys.com/Sure_Cure_GM_6_5_Lift_Pump_Solution_Kit

6. An EGT and Line Pressure Gauge hooked into the multi-gauge - switchable between gas pressure - and/or quality so you can see what the line pressures are as you drive. See https://bigbay4bestbuys.com/content/hydrogen-purity-gauge-and-controller.

7. A multi-gauge like Ultra-Gauge, Torque, or Dash-Command (these will read horsepower, and if set up right instantaneous real time fuel mileage)

8. We recommend running a sodium silicate type "block and head seal" - because ALSO with the GM Diesel - it suffers from the same thing the small black Chevy engine does with the two rear cylinders where the water passage is too close to the cylinder sealing ring and and it may develop a leak just "slightly" there - not enough to cause high pressures in the coolant - but enough to cause a soft misfire in those two cylinders which will be exasperated in bi-fueling as a imbalance and ignition delay in a Diesel - e.g - a source of a light diesel rattle also. Obviously if you are loosing coolant slowly at all - that is a tell-tale sign too !!

The Quick Skinny

It does not matter what you "think" about your 6.5 - if it does not have a Sure-Cure lift pump it is not running properly becasue the GM Stock design of lift pump is not producing enough PRESSURE consistently to properly run the engine. See https://bigbay4bestbuys.com/6_5_lift_pump

Poor quality Diesel fuel - will cause ignition delay and MORE rattle because if you are using CNG - the combustion chamber temperature will not be sufficient at idle or driving to light the CNG and you will get "black smoke" from unburnt diesel and actually poorer performance. Typically CNG needs 1,500 F degrees to light sufficiently immediately between 5 and 15% concentration and usually will not light above or below those concentrations well if at all.

When driving - the PCM will "think" the engine is not producing very much horsepower - and hence the transmission line pressures will be low, allowing the transmission clutches to slip under acceleration until the output shaft determines they are slipping and raises the line pressure. That slippage will steal life from the transmission and create added heat. See also http://www.novak-adapt.com/knowledge/transmissions/automatic/4l80e

The Devil is in the details

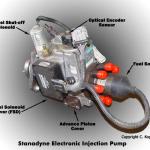

if the engine is not running in "tip top" shape - a sticking injector you do not "think" you have will show up as smoke and more rattle. A GM 6.5 idles very quietly - so if there is any improper knocking or rattle that goes away as you accelerate on plain Diesel - you have likely got a sticking injection and / or poor fuel pressure to the IP resulting in weak pop pressures to the injectors - which on a 6.5 GM Diesel ARE mechanical injectors - even though the IP is electronically controlled. The truth is persistent use of a good high lubricity additive for performance enhancement will dissolve carbon deposits on and in the injectors over time - which cause them to "stick" - or spray un-even fuel patterns - which shows up as increased idle engine noise - or increased idle speed as the PCM will try to keep the engine running as a sufficient RPM. If the engine will not idle at 600 rpm when fully warm - you have poor fuel, poor fuel pressure to the IP, or an injector issue.

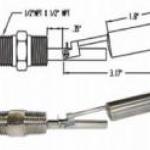

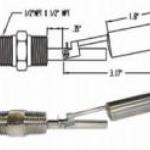

The line pressure "force motor" properly called an "EPC solenoid" is available in an adjustable version from several vendors - Borg-Warner being the most well known and it is their part 50058. On the end there is a T-20 screw in the center and 1/8 turn clockwise - but no more than a 1/4 turn will increase the line pressure when driving so it does not drop below 55 to 60 psi in city drving in town or below usually 85 psi on the highway - when fumigating - also called "bi-fueling" You can install the line pressure gauge first and measure it BEFORE you make any changes to see whatit going on. On acceleration from a stand still line pressure will go solidly to 100 psi or above depending on how heavy your foot it. It is easy to replace yourself - but be advised before you drop the pan - there is more often than not a T-25 screw holding it in - and nothing but a T-25 screw driver or socket driver will get it loose. You cannot get on the side of it with vise grips - it has a smooth convex pan head. So get the right tool first.

AND . . . frankly you need to "see" the operating transmission line pressures as you drive and as it shifts - BECAUSE the PCM will not believe and know the engine is putting out the horsepower it is - and you WILL BE slipping your transmission a lot.

The 4L80E transmission features two speed sensors, one for turbine input speed and one for output speed. It uses the Input Speed Sensor to monitor input speeds to compare against engine speed and output Shaft Sensor speed, using this data to adjust shift speeds under instantly detectable conditions. The PCM can command the engine to momentarily drop power during a shift if there's a possibility of clutch damage - and it can command higher line pressures to hold the clutches tighter - a too-common problem in transmissions of other makes. Shift stabilization is achieved through these and similar strategies. HOWEVER - when bi-fueling it cannot command the bi-fuel mixer to do "anything"", so you CAN damage the tranny with low line pressures. Grade braking and clutch line pressure (for greater holding power) are additionally great features that are activated by Tow / Haul mode on the truck platforms.

Before you drop than transmission pan - and of course be prepared to change the transmission fluid and filter - about at least a week before - put a can of SeaFoam Hydra Trans Tune in it. See https://seafoamsales.com/hydra-trans-tune/ The shift solenoids do tend to get a little gummed up and you would be surprised - how what you think is normal and good running and shifting transmission might get even smoother. SeaFoam Hydra Trans Tune is a high solvent product and it is best to use it to dissolve and then drain it away in a fluid change. If you are one who does not like to drop tranny pans because of the mess - or your does not have a drain bolt - use a cheap hand pump to suck most of it out the dip stick tube first with a long length of 1/2 poly tube and a hand pump like this => https://www.harborfreight.com/multi-use-transfer-pump-63144.html then when you drop the pan - only small amount - maybe a quart will left in the pan an if you are careful you won't spill it.

When you are running down a highway fumigating - a.k.a "bi-fueling" - and everything is working properly - a Multi-Gauge will directly report between 2 and 15 horsepower is being generated, and unless you have turned up the line pressure, you will see transmission line pressure drop to idle pressures of 40 to 45 psi, and the transmission will be "borderline" slipping. The inout and output speed sensors will be trying to keep the line pressures high enough to prevent clutch slippage but not doing a good enough job of it.

Effectively what is going on - is the engine is running on more of the bi-fuel - fuel - like CNG or Hydrogen and the timing and fuel being used is about that which is required for idle - until to hit a hill or go to pass someone. You will be getting 50 to 70 percent better mileage at that point.

Be advised - if you are running straight CNG - the slightest incline will climb easily - and so will the EGT (Exhaust Gas Temperatures) - and it can get to 900 and over 1000 very quickly. On Hydrogen not so much - but ALSO be advised we are talking about TRUE pure Hydrogen - NOT what is called "HHO".

Conclusion and just plain good sense

Our vehicle cruises at about 600F to 700F EGT on the highway - over 900F - YOU SHOULD GET OFF OF IT, you can blow head gaskets and overheat it really FAST. ----- AND it will just keep running just as strong until you "blow it up" which will happen without warning and very quickly. You can MELT PISTONS running at high EGT on CNG or Propane. CNG is a worse fuel to bi-fuel with than Hydrogen - Hydrogen actually will cool the engine as it burns - and it runs quieter with far less ignition delay too because while its auto-ignition temperature is high up around 1,200 f also like CNG - it's flammability as to range of concentration is wider - between 4% and 75% concentration it will still light off - and so that means Hydrogen ignites easier on even crappier Diesel fuel. What you get is complete burn and a cooling charge of exhaust gas as Hydrogen turns to steam vapor which actually cools compared to the hot burn of CNG - or Propane.

,

,  ,

,

,

,  ,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,

,

,

,

,

,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,

,

,  ,

,  ,

,

,

,  ,

,

,

,

,

,  ,

,  ,

,  ,

,

,

,

,

,  ,

,  ,

,

,

,  ,

,

,

,