Fumigating a Diesel Safely

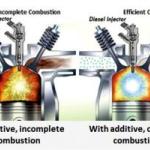

Generally, diesel engines produce high levels of NOx emissions and significant smoke and particulate material levels. Generated smoke may be classified as "Hot Smoke" or "Cold Smoke". Hot Smoke results from incomplete combustion during heavy engine loads. Hot smoke also results from an over-rich fuel mixture. Insufficient oxygen prevents the diesel fuel from completely oxidizing. Besides generating particulate pollution, hot smoke performs no useful work; it reduces net engine power and lowers vehicle mpg. Traditional engine adjustments do nothing to hot smoke production. Fumigation reduces most hot smoke production resulting in reduced pollution and increased vehicle mpg.

Case study - "how to" => https://bigbay4bestbuys.com/fumigating_GM%206_5_diesel

Where it all REALLY starts is the quality of the diesel fuel in the first place. Diesel today is crappy - everywhere - as no one can tell what it is they are buying - they cannot tell appreciably when a load of diesel is of high cetane rating - because generally is it ALL the lowest cetane it can be and still be called "diesel" #2. what has this got to do with fumigating ??? Well, simply put "detonation is detonation in any engine" - and if you do not have controlled combustion - at a certain time - you have "detonation" or ignition delay - and a loss of horsepower that might have been - and should have been - developed - PERIOD.

Sure, the Turbocharged diesel engine makes up for some of this low cetane diesel - but when you fumigate with CNG especially - all you get is ignition delay of the CNG - which then results in uncontrolled combustion and a lot of potentially engine damaging "rattle" and high EGT because of unburnt fuel going don the pipe still burning. WHY ??? CNG auto ignites at 1,200 F, and if the diesel fuel is slow igniting in the regular operation of the diesel engine - then it won't ignite the CNG in a timely fashion either as that is your "liquid spark plug". It is the same effect in a traditional gasoline engine where special hot plugs should really be used n CNG fueled vehicles - because it takes 1,200 F to light CNG off - and remember that CNG only lights between 5 and 15 percent concentrations. BUT until a diesel is FULLY warmed up to operating temperature the ignition process is not that "sweet spot" ideal situation where a diesel runs best and is at its quietest "purr". Plain and simple the diesel ignition and combustion process is a complex and ever changing one until fully warmed up - and in fact a diesel performs best at a static load scenario like an 18 wheeler pulling a fixed load down a flat highway - or a locomotive doing the same to turn alternators to power the locomotion of the train. (yes that is how they work)

Thus a diesel is a load dependent engine and smoke produced during light engine loads is called "cold smoke". Traditional engine adjustments (engine timing and advance), leaking injectors, and poor quality diesel fuel are the contributors to cold smoke. Cold smoke produces the same emission pollutant particulate matter. Fumigation does not abate cold smoke.

Mandated reductions have forced manufacturers to reexamine the diesel engine combustion process to discover answers. For four-stroke diesel engines, fumigation is a relatively low cost and easily adaptable solution. The major issue to deal with is increased EGT's.

Also you must consider crappy low cetane diesel too.

What is Fumigation?

A fumigation system injects a gaseous or liquid fuel into the intake air stream of a compression ignited engine. This fuel burns and becomes a part-contributor to the power producing fuel. While alcohol and gasoline may be used, gaseous fumigation seems to exhibit the best overall power yields, performance, and emissions benefits. LPG (Liquefied Petroleum Gas) or CNG (Compressed Natural Gas) is used. The fumigation process is divided into major fraction and minor fraction fumigation. When more than 50% gaseous injection is used, it is known as major fraction fumigation. Minor fraction fumigation is under 50% gaseous injection. One after-market fumigation component supplier, Algas Corporation, using 20 to 25% fumigation rate, reports excellent performance benefits and reduced target emissions. One test for a 1984 6.9 liter diesel engine in an F250 chassis showed a 64% reduction in NOx and 45.2% reduction of particulates. CO was almost unchanged. However, total emissions of hydrocarbons in grams per mile increased (see graph below).

Graph courtesy of Algas Corporation, a Division of Precision General Inc.

History of Fumigation

Rudolph Diesel's 1901 patent mentions the diesel fumigation process. Not until the 1940's were there any commercial fumigation applications. Cooper-Bessemer introduced large, big-bore, stationary engines which ran on 95% natural gas and 5% diesel. Since then other manufacturers have used fumigation to boost power output. Fumigation has been successfully used in agricultural machines for many years. Texas and Colorado were first among the states to accept fumigation as an alternative fueling method. Now the EPA accepts it nationally IF it passes conformity to the emissions standards on the engine as vended by an EPA registered manufacturer. In California the Air Resources Board (a.k.a. "CARB" or "ARB") calls them "vapor systems" or "vapor injection systems" in the Executive Order (EO) database library. Today in theory one can STILL run a 95 / 5 mix - IF and only if the load is light and kept in a VERY narrow rpm range - slowly getting up to full load. That is not the real world however with the EPA FTP driving loop which is the standard fumigation systems are measured by.

Benefits

For nonstationary variable RPM engines, variable ratio fumigation is more effective than fixed rate fumigation. As a result, engine load and fumigation rates are approximately matched like a throttling effect even though a diesel is throttless engine. Reduced NOx and particulate emissions are the most outstanding benefits. Minor fraction fumigation yields significant (up to 25%) gains in smoke-limited torque gains. There are other technical non-pollution related gains. Tests show reduced exhaust temperature, reduced crankcase solids, reduced injection service and longer acceptable crankcase drains. Diesel exhaust odor is also reduced.

How Does It Work?

The major engine modifications include:

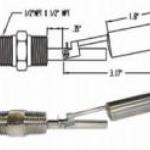

-- addition of a venturi-draft tube in the air intake system

-- secondary fuel tank, safety controls, and switches

-- acceleration-deceleration control valve

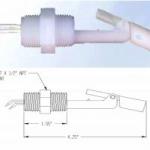

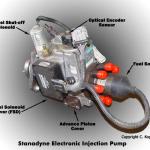

-- microcomputer control. (See Figure 1 below)

Figure 1.Courtesy of Algas Corporation, a Division of Precision General Inc.

The venturi-draft physically introduces and mixes LPG or CNG with the air charge. Since diesel engines operate with near zero manifold vacuum, an air-venturi draft tube is necessary to create a signal proportionate to engine speed. During installation the baffles and the tube are calibrated for fumigation onset and maximum fumigation rate. The fuel mixer is added to the draft tube. This provides the point of introduction for the gaseous fuel. Mixer calibration is based on the maximum fumigation rate. Fuel regulators differ for CNG and LPG fumigation systems. Since CNG tank pressure may reach up to 3,600 psi a primary regulator is necessary. LPG fumigation systems do not require this component since tank pressures are less than 300 psi. A secondary regulator allows the LPG or CNG to expand to a gaseous state. This regulator provides a safety factor and locks out fuel flow in the event of a system failure. This is known as a two stage mixer.

The acceleration-deceleration control precisely times the fumigator fuel. If fumigation occurs prematurely on acceleration or is late in turning off on deceleration, fuel is wasted. Late fumigation on acceleration produces a lean, poorly combusted power cycle. Drivers notice a power lag on acceleration. This control instantly senses a change in engine load and responds by properly adjusting the fumigation rate for the required diesel-delivery rate. The control output signal results in the opening or closing of the mixer control valve. This valve controls the fumigation fuel flow rate.

Properly sized LPG/CNG fuel tanks are necessary to provide fumigation for the quantity of diesel carried. These tanks must meet state and federal safety requirements. In some locations, installation position (i.e., inside the frame) is also regulated. The Diesel Fuel Limit Switch prevents excess fuel delivery when the fumigation system is active. This switch prevents over fueling which wastes fuel and produces exhaust smoke. This switch allows 100% of diesel flow in the event that fumigation fuel ceases to flow.

The microcomputer controls the functions of each of these devices. It performs the logic function to ensure that the system operates within design parameters. It also can sense malfunctions allowing the engine to default into a standard diesel, nonfumigated engine.

Today, most ALL diesels are ECM - computer controlled and OBD-II compliant - but that doe snot make up for crappy low cetane Diesel. There is now way the ECM can accurately compensate for a fumigation process that is NOT controlled by the ECM - it is controlled by air flow and the venturi effect it creates of a light vacuum. You can install a "power valve" which is simply a restriction to not allow the vacuum to pull open the final stage of the mixer - or you can increase the cetane of the fuel to halt the ignition delay problem.the power valve is not the best solution because you loose horsepower gains - especially on a HCNG system - that is you have to decrease the amount of power the CNG or HCNG is responsible for developing, and that means greater use of the more expensive Diesel fuel side of the fumigating equation.

To increase the cetane of the fuel is the ideal scenario but we cannot tell you how - though we have our own proprietary cetane booster and lubricity enhancer which allows a high use of CNG - which decreases the ignition delay - and the engine runs great and QUIETER without CNG - and that is when you know you had crappy diesel after all. If you review the refining process and see the points are which certain fuels by how they (at what level of distillation temperature ) they come off the cracker (distillation tower) you can get a clue about what will increase the cetane rating and what will decrease it. A higher cetane lights quicker and more easily without delay and that is what you are after especially when fumigating with a fuel that is hard to light anyway.

We cannot publish non-EPA approved formulas - but thankfully cetane booster and lubricity enhancer is available commercially - and believe it or not - it in this case is actually worth the price. Here is hint a lubricity enhancer is used in fueling a two stroke motor in the fuel also. After all Ultra Low Sulfur Diesel (ULSD) found in all diesel pumps by mandate of law is good to reduce emissions, BUT is not good for ANY diesel injection pump even with ceramic pistons today to take the extra wear that drier less slippery fuel causes. If you do not know what this article is talking about - you need to do a lot more reading elsewhere about ULSD.

And now - guess what - our HCNG fueling system solves most of the issues mentioned above, and since you make your own fuel - your pocket the cost of fuel for other uses.

See also https://bigbay4bestbuys.com/content/hcng-mixer-diesels-cng-and-gasoline…

,

,  ,

,  ,

,

,

,  ,

,

,

,  ,

,  ,

,

,

,

,

,

,

,  ,

,

,

,

,

,  ,

,  ,

,

,

,

,

,

,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,

,

,  ,

,  ,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,