ANSWER: Help me with the GM 6.5 diesel

It is important that your engine is running properly. If you just bought it - change the fuel filter and put algicide in the fuel tank and be prepared to change the fuel filter two or three times. You would be surprised how many diesel tanks have algae. Of course change the oil and air filters and use a good quality Diesel oil

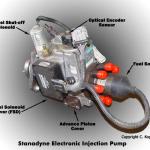

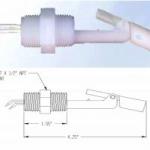

The biggest problem with the 6.5 is the lift pump GM supplied DOES NOT WORK - it limps along as a pump and it will not pump the required pressure to the IP and this results in a host of issues from running the IP slightly "dry" to burning up the PMD also called the Fuel Solenoid Driver or FSD, and the Fuel Solenoid on the end of the IP in the center of it which also acts as the "throttle" on the DS4 injection pumps. The FSD also known as the PMD and the Fuel Solenoid are two different things. The Fuel Cut Off Solenoid is yet another different hing. See https://bigbay4bestbuys.com/6_5_lift_pump and our solution that WORKS => our Sure Cure Lift Pump Solution Kit=> https://bigbay4bestbuys.com/Sure_Cure_GM_6_5_Lift_Pump_Solution_Kit

If you have a relocated PMD make sure it is in cool outside passing air flow - like right at where the hood closes so cool air will hit it FIRST when moving into the underhood area..

No matter what you have read elsewhere - you need OVER 5 psi at the IP at all times, and the only way to check this is with an inline fuel pressure gauge. Otherwise you are just slowly killing your IP. It uses the fuel oil PRESSURE also for immersion lubrication and by recirculation of excess fuel to the tank for cooling of the IP itself and the PMD attached to the side of it in stock configuration. Spec pressure is 10 to 14 PSI, with 9 psi at idle or wide open throttle ideal after the fuel filter. at all times. The stock lift pump will NEVER do that.

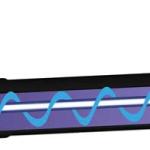

The turbo and weak vacuum to it is also a problem - as even a slight vacuum leak will cause a loss of boost, and usually this is because GM used hard polyethylene plastic lines which over time may have partially melted or cracked or have loose connections now where the rubber lines connect to them. Do not band aid the situation by changing it to a spring operated mechanical waste gate system, - a.k.a. a "Boost Master" or variant as that will just screw up the timing from the ECM / PCM.

For instance if the boost solenoid is disabled, unplugged or not working the KOKO precise timing setting procedure will not work. The PCM and Injection Pump manages timing electronically depending on engine temperature and perceived fuel quality - a.k.a. how much horsepower it thinks the engine is producing - and will adjust the timing or try to. If the scenario is particularly bad it may go into limp home mode an then you will really get poor performance and possibly black smoke.

You should be able to hear and feel the turbo spool up on even light acceleration, and a boost gauge will show 3 to 5 psi of boost. A WEAK vacuum pump however will also give poor boost because the normal position of the waste gate is OPEN, and it is held shut to produce boost by vacuum. Therefore poor vacuum at idle will affect initial acceleration boost. Usually you can hear a poor vacuum pump as a persistent light knock at the vacuum pump area which means the cam is worn low on the vacuum pod.

Poor or low quality fuel also may not produce enough heat and exhaust velocity to spin it fast enough as well as any misfiring cylinders - which may be the source of a knock. See also https://bigbay4bestbuys.com/cetane_booster

The mechanical injectors clog easily with carbon from poor combustion of fuel. the nozzle holes are very small - it does not take much to clog them = either from foreign debris coming into them (i.e. someone changed the injectors with dirty hands and let grease particles into the injectors) - or from low injection pressures allowing fuel to partially combust INSIDE them because of poor pressure to inject fuel or they being partially stuck open from either of the above reasons.

As said, the vacuum waste gate on the turbo is normally open so if you have weak vacuum you will also get lagging or weak boost if you have a vacuum waste gate and weak vacuum or a bad waste gate solenoid or cracked or melted partially plastic tubing lines.

If you have mechanical spring operated waste gate on a 96-02 OBD-II engine someone has hacked a mess in the engine and that is one reason it won't really run right.

If you still have a PMD you have a DS4 electronic IP on an F motor which should. Not have EGR - only an "S" motor has the EGR system - it is determined by the eight digit in the VIN.

LONG story short make sure the vacuum pump is working and the lines are tight, makes sure the vacuum waste gate and a waste gate solenoid are hooked up and working, on and make there no vacuum leaks and it you find any and fix them start running right - or better again

The PCM does not handle timing adjustment properly to the DS4 when the boost solenoid system is missing

Once the engine gets warm do the KOKO timing procedure - it can never hurt. You would need a scan tool - like a Modus or Palmer Engineering PC hook up with the GM Diesel licensing option to see what it is an what it changes to.

But most importantly - again get a positive displacement actual lift pump that will put and keep spec inlet pressure to the IP, like the Sure Cure Lift Pump Solution

The OEM solenoid lift pumps do not work or for long at spec pressure even new The 6.5 Sure Cure Lift Pump will end all the ridiculousness of poor performance hard starting and blown PMD"s which are all related

As an example all kinds of weird hard starting issues , erratic boost, and poor performance was going on and it was caused by a melted poly vacuum line on the manifold, a rusted waste gate solenoid due to condensation moisture being sucked in that melted line, a weak vacuum pump wearing out, and a loose main vacuum hose on it too, and the timing being out 1 degree which the KOKO procedure corrected

One cannot run mechanical waste gate and over boost the 6.5 an expect it to run right. In short if it has mods like above, put it back stock or you are fighting the PCM computer and you will not win

The limp home mode burns more fuel, has crap performance, and runs hotter EGT"s and it will stay that way and likely never throw a check engine code

One cannot just throw parts at it. The said truth is the 6.5 lift is Not a pump - it is a solenoid driven spring operated pusher. If the spring weak - it buzzes but does pump pressure even though it will move fluid unrestricted

Without about 7 to 9 actual PSI at the IP at idle Or Wide Open Throttle. The OEM Pump does not work by its very design

You can go through 12 OEM style "lifetime warranty" lift pumps all failing spec pressure in between in 1 week to a few months coming back as sluggishness or blown PMD's and cut outs

Finally enough was enough and Sure Cure Lift Pump ended all the problems

The DS4 MUST HAVE Above 5 PSI Pressure to it at all times to work properly PERIOD

Having worked with a Stanadyne authorized rebuilder, repaired them and the test stand to check the rebuilds to spec, I can say that is the Stanadyne required MINIMUM pressure but the DS4 is designed to take up to 15 PSI and has a check and return valve system to regulate internal pressure to 9 to 10 PSI and return excess so as to circulate fuel to cool the PMD and internally lubricate the IP as well as act as the first stage to multiply oil pressure for injection and to cause idle. If the DS4 has proper pressure to it = it will recirculate fuel to the tank to cool itself and the PMD attached to its side, and it will not blow PMD's.

The PMD is only meant to assist in throttle - not control it. When there is low inlet IP fuel pressure the PMD through PWM strains to hold the fuel solenoid (on the end in the center) more open for fuel that is not there. This blows PMD's and burns up Fuel Solenoids which is the reason for 90 percent of DS4 rebuilds are needed/

So... it is not the DS4 that is junk it is the lift pump GM chose to use against Stanadyne's advice.

Of course the DB2 as a full mechanical IP won't suffer this except while it may keep an engine running or start on low fuel pressure low inlet fuel runs it drier for internal lubrication and it just then dying a slow death.

So it is the lift pump and the pressure is critical if want the IP to last longer than not

Some oil from the turbo is normal in the manifold or cross over but a lot is not

If you take off the air intake hose to the turbo, the turbo should spin freely by finger spin with no roughness of any kind.

A knock can also be caused by a worn cam in the vacuum pump (if your engine has one) or caused also by air in the injector lines if you have had the injectors replaced. Air results in that injector not fully functioning - and often does not work its way out by itself.

The GM 6.5 diesel is a quiet running Diesel engine when working properly, and should give performance comparable to the 400 cubic inch gas engine

When the diesel warms up the oil thins and the parts expand - knocks from loose fits get worse

You can drop the oil pan easily

Sometimes you just have a noisy engine and it can be a host of things that also sounds sometimes like bad lifters

Lifters do not often go bad on the 6.5, what happens is the rod bearings wear and that results in lower upper end oil pressure, which in turn wears the rocker arms badly and there are plastic keepers that then let the whole thing rattle terribly because they get hot, brittle and crack out or fall out. A Diesel beats on itself and one running on poor fuel really beats on itself from ignition delay firing.

Oil pressure should be about 22 psi at idle and around 40 driving. If it is lower than that, at the very least consider putting in .001 oversize rod bearings - use a plasti- gauge to make sure clearances are not too tight. That will raise oil pressure. The mains usually are still spec in at std size. You can see the keepers as the yellowish buttons in the middle of the rocker arms in the pic

You can replace it or rebuild it with parts to make a new one using a Rocker arm shaft =>

And Rocker arms as needed

And using an undersize Rod bearing .001 can be done by a direct replacement with no machining to raise oil pressure - but use plasti-gauge to make sure they are not too tight

and new retainers which are item number SEALED POWER MR-1948B - the yellowish button in the above pic

Discussion about the keepers =>

https://www.thedieselpageforums.com/tdpforum/showthread.php?t=24226

If you do decide to replace lifters - you should also replace the camshaft - as new lifters on an old cam can run lobes flat even if they are roller lifters

Check oil pressure and do the bearings and rockers first and then do a compression test before ripping into the engine - because you have to take the IP out to get to the lifters. Replacing the rocker requires no adjustment or skill - they are self adjusting..

If you then have a weak cylinder on compression testing - do the oil in cylinder test to see if it is the valves or the rings. Harborfreight.com <http://Harborfreight.com> used to sell a compression tester with the glow plug adapter included for testing a gm diesel

If it is just a really noisy valve train - do the oil pressure boost things - or even the quick and dirty two bottles of Lucas oil treatment in an oil change to see if it quiets and oil pressure comes up if it is low

Assuming you have not had it since new, some one else would have had to really beat it badly to damage the lifters.

Remember also - a sticking injector on a 6.5 can also sound like a bad rod and will make the top end rattle badly as well as so will bad fuel. they are mechanical injectors on an electronic DS-4 IP. On the 6.5 poor fuel pressure to the IP can cause all of that also as the injectors get carbon'ed up internally due to low injector pop pressures. Using "marine injectors" can also do this on a weak IP. Rebuilt injectors are just replaced injector nozzle assemblies that have begun to stick because they are carbon'ed up internally. A partly stuck open injector not only will make the whole engine run like crap, it can create internally a cylinder and exhaust gas temperature high enough to burn a hole in the piston.

Diesel fuel today is crap, it is ULSD which the Stanadyne IPs can be shortened as to life by it , and it is de-blended to burn cooler to reduce NOx emissions, both of which will not give exhaust gases really hot enough to spin the turbo well. A good fuel additive used religiously will clean the injectors.

Use of an additive makes the 6.5 run so quiet one can hear the IP running like a watch and the injectors popping. Of course you need to know what it sounds like and usually involves hearing one running on the test stand freshly rebuilt to spec.

Much of most diesel noise and rattle of a diesel is actually ignition delay of the fuel because it is low cetane, The mechanical ip 6.5 will run on anything, but really likes 55 plus cetane fuel because of its pre chamber head design. The

DS4 version will run on anything also that is clear enough for the optical sensor to see through. That is also why it can run so quiet because the timing is adjusted on the fly by the DS4, and and even the DB2 versions are quiet and for that reason the military uses them.

A 6.5 diesel with an intercooler setup will perform better especially on boost. The 6.6 Duramax has an Intercooler as standard equipment, closely the same engine - except for the common rail and more costly electronic injection and injectors.

Use an Ultragauge or Android program with a bluetooth connection so you

see the difference moving through the air cools the Intake Air Temperate and gives better performance. You will be able to watch it go up and down

whether you have a DB2 mechanical injection pump, or D$4 electronic, what makes the biggest difference is going to be getting a positive rotary vane lift pump on it - the Sure Cure GM 6.5 Lift Pump kit.

If you have an electronic DS4 then the vacuum pump and lift pump pressure is critical, because the vacuum pump is what allows the turbo boost gate to work properly, and a weak fuel pressure DS4 IP performs like a dog while it slowly

kills itself and the PMD

spending time in a Stanadyne authorized rebuilder shop which specialized in rebuilding the Stanadyne Diesel injection pumps (IP) on the 6.5 Diesel and installing them as well as other mechanical repairs showed the quirks of the 6.5 all related to the unreliable lift pump.. While the 6.5 mechanical version

IP can actually try to continue to suction pull fuel and keep the engine running - it runs very poorly while the DS4 electronic version will not (it should have at least 5 psi at all times) - it will just quit, and over time while it will run on as low as 1 psi, it will blow the PMD due to weak fuel pressure. this happens becasue teh fuel solenoid goes to 100% duty cycle trying to hold the throttle open to keep running, when it is actually fuel pressure which should keep it balanced and open just enough. Both are hard to start when the fuel pressure is weak. The re-circulation function of the fuel pressure return valve in the IP also helps to keep the injection pump cool and well as immersion lubricated in high pressure fuel oil of around 5 to 9 psi. Our article at https://bigbay4bestbuys.com/6_5_lift_pump shows why

But until a person sees what fuel pressure does on the test stand where the IP's were tested and how injection rates are affected you do not understand HOW CRITICAL IT IS.

On the DB2 weak fuel pressure also results in scarred piston plungers that create the injection pressure - wearing them down and necessitating a rebuild - usually easily told by pouring cold water over the pump which makes

it work better for a short time or able to get the engine started (the mechanical version only) and on the DS4 it puts also a high electrical load on the fuel solenoid often burning it out - which can only be properly replaced during a bench tear down and rebuild, and also blows the PMD with regularity - often within one week it has been seen.

A lot of these Diesel stores and online shops and self help websites have people answering and diagnosing things about the 6.5 who really do not understand the engine and its fueling systems

The moral of the story is to warn that if you have not checked the actual pressure the lift pump puts out or if it has not been changed to a rotary type pump you will not get the full potential even an inter cooler can produce

when you are done and you loose horsepower there too as well as slowly damage your IP.

Every 6.5 has an oil pressure gauge and as soon as you get to 1500 rpm you should have full spec oil pressure - around 40 psi

Cold first start it should go to around 55 to 60

Factory says minimum 10 psi at idle - but that is too low and a sign of

bearing wear

22=25 psi at idle warm is ideal

People have changed oil in diesel engines and used cheaper conventional motor oil and if that was done over the life of the engine it definitely has rod bearing wear. 140 K on conventional motor oil is like 300K of beating the engine

A Diesel beats on itself - especially with poor cetane fuel and a good heavy duty DIESEL motor oil is critical

A broken keeper on the rocker arms will let the rock arm slide sideways and it will also produce a knock as well as a lifter tick sound also

Unfortunately to take off the valve covers means removing all the fuel injector lines to inspect

GM made a book called 6.5L diesel Engine EFI/Mechanical Systems it has a part number of 16015.20-4 for the 1997 and up engine - it is hard or impossible to find but worth it

If you have lower oil pressure get bearings - Mains and Rods .001 undersize and have them ready and then drop the pan and inspect. Get plasti-gauge also. Check side clearance between the rods - and even look for evidence of

hydro-lock - a curved connecting rod

If you are own mechanic then it is just time and grease

But as said before weak lift pump fuel pressure will mean extra wear on the IP and it result in weak pop pressures and that will also cause an ugly KNOCK sound if an injector is not able to open along with the others. Again when cold the IP will work fine - but as it warms up - it too will expand making lower pressure to pop the injectors and one plunger that is weak is all it takes. Hence

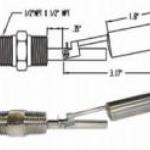

the cold water trick for the mechanical IP. A good solid lift pump other than the GM POS that comes with it might go a long way to solving it . A person can literally go through 12 of the GM lift pumps in two years - and they will all fail in between one week to one month - and before putting on the Sure Cure Lift pump you will LIKELY have repeated trouble because the replacement pumps are not built to any rugged spec to last, but sine they are spring operated pumps they are just going to fail - period. Get a fuel pressure gauge and check the IP inlet fuel pressure. It should be 10 to 14 psi. There should be a check point in the system that is a a refrigeration type Schrader valve.

If it less than near that pressure get a new reliable lift pump FIRST

If you have a sticking injector lots and lots of performance additive lubricity cleaner - eventually within a year of constant use it MAY eventually dissolve the carbon deposits usually clogging them and then the idle will come up up smooth and quiet.

it is just a witch of an engine you have to come to know and treat well or one slight other thing can cause major issues in performance

If you have bigger problems than that above - this article will not help you

| Attachment | Size |

|---|---|

| how_lift_pump.jpg | 898.24 KB |

| one_way_valve.jpg | 787.2 KB |

| solenoid_lift_pump.jpg | 28.86 KB |

| disgust.jpg | 44.23 KB |

| prechamber.jpg | 72.21 KB |

| 6_5_rock_assm.jpg | 137.58 KB |

| 6_5_rock_shaft.jpg | 62.32 KB |

| 6_5_rocker.jpg | 5.82 KB |

| 6_5_rocker_button.jpg | 179.47 KB |

,

,  ,

,  ,

,  ,

,  ,

,

,

,

,

,  ,

,

,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,

,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,  ,

,

,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,

,

,

,

,