What makes diesel fuel good or bad ??

There are a lot of articles all over the web where well meaning people are trying to explain something they truly do not understand. The Chemistry of PETROLEUM and its refining.

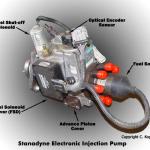

What happens if I put Gasoline into my Diesel Car ?? ANSWER: You RAISE the CETANE and lower the lubricity of the existing fuel in the tank - to a certain point where if you put in too much, you will lower the lubricity enough to damage the diesel injection system. ANY amount of Gasoline will LOWER the Lubricity and that is not good, and the solvent nature of Gasoline depending on the age and type of Diesel engine you have can soften and destroy seals - but that REALLY is a worst case scenario . . . and you have to be using a LOT of Gasoline to accomplish that, it is more likely low lubricity and high heat of combustion and friction throughout the high pressure injection pump and injectors themselves will wreck the injection system first.

Did you ever wonder why sometimes - if you drive a Diesel - you go to the station to get fuel and it seems to be a particularly "HOT' batch - and your vehicle runs great ?? More power, easier starting, idles quieter, runs smoother, less exhaust smoke ?? Well you probably got a load that came out of the tanker right after it made a delivery and had gasoline for the previous delivery. Other times it is pure crap - or why a station drops the price of its Diesel quite a bit ?? ANSWER: The fuel usually has been sitting too long and is in danger of growing or getting algae - or already has algae in the fuel. (It is OK to buy as long as you treat what you buy with a "Bio-Kill" diesel fuel treatment immediately upon it hitting your tank.) It only takes about half an ounce per gallon of gasoline for you to feel the difference in power and see the difference in less smoke. So for a 4000 gallon diesel delivery - it would only take the residue of 10 to 15 gallons of gasoline to make a difference you would feel. All tanker truck tanks have baffles and support plates inside to reduce sloshing during transport and fuel gets caught on those plates and the residue alone is enough to add up to a few gallons of gasoline compounds which then dissolves into the diesel.. See http://www.nomenclaturo.com/wp-content/uploads/Grenada-Tank-Trailer-Terminology-Diagram.jpg

In 1983 - VW Diesel Rabbit and Audi manuals even RECOMMENDED using up to 10% Gasoline (10 gallons to 1 gallon) in the Winter months or cold climates for easier starting and more power in the Winter or high mountain altitudes. A 1981 Mercedes manual said the same thing - and even the same era Caterpillar manuals said the same. Now BEFORE you rush to put Gasoline in your Diesel remember in 1983 - Diesel fuel was STILL high sulfur diesel and the decrease in lubricity to the fuel would not harm anything in that low of a concentration. Also remember unleaded fuel began in the US in 1974 - but not in Europe. The first European countries started replacing lead by the end of the 80's and by the end of the 90's leaded petrol was banned within the entire European Union. In the US a gradual reduction of lead in gasoline since the early 1970s. "Regular" gasoline typically contained approximately 4.0 grams of lead per gallon; average lead content was reduced to 0.5 gram/gallon in 1985, and still further to 0.1 gram/gallon in 1986.

So in 1983 - even Gasoline had LEAD as a lubricant still in the fuel in Europe - where the manual and wisdom came from, TODAY you do not dare put Gasoline in the Diesel fuel as it is a dry solvent and can quickly damage the injection system unless a lubricity enhancer is added in sufficient quantities. Add that to the fact that most diesel fuel is Ultra Low Sulfur Diesel (ULSD) - low in lubricity already - is a double recipe for disaster - but boy it will run great as you are killing it.

A small amount - less than one ounce of Gasoline - lubricity enhanced as a MUST - per gallon will bring UP the API gravity of the fuel. That is a good thing. That is effectively raising the Cetane index AND BTU per gallon. The diesel will start easier, run quieter, have more power - but it will also be higher in the Exhaust Gas Temperature ranges - not good - especially if you have a Turbo or are in a pollution controlled state where NOx might be measured. So you NEED an EGT gauge to watch closely and you should have a Hydrometer to see what you are doing to the fuel. It will have the characteristic "benzene"and "hexane" Gasoline smell - but it is simply an enhanced higher Cetane diesel fuel. A good - meant to burn - "safe" lubricity enhancer is common 2 stroke oil, and a safe ratio is 75% two stroke oil - 25% gasoline - at NO MORE than 1 ounce per gallon of diesel fuel. This should not make the fuel "illegal" - i.e. over 15 ppm of sulfur. If you buy two stroke oil by the gallon at - say - Walmart; usually this mix adds only 3 to 8 cents per gallon - to a gallon of Diesel fuel - way cheaper than commercial additives. I can never be sold in a store as pre-mixed product because primarily the Gasoline as an additive to the oil makes it STILL too volital to sell indoors as a retail item,AND it would require a metal can like Coleman fuel is sold in.

The reduction in the sulfur content in the diesel fuel from 5000 PPM to the current 15 PPM has significantly lowered the lubricity of the fuel and fuel lubricity is not being checked in the field. The use of 2-cycle engine oil will help the lubricity issue but the problem is the oil if used straight, ,when burned in the combustion chamber, can leave deposits in the combustion chamber because adding the oil alone will lower the cetane rating and API gravity. the best 2-cycle oil for this application, is the marine grade. The additive packages are radically different between the hot engine 2-cycle (engines water cooled with a radiator or air cooled) and cold 2-cycle engines (out board engines with an open loop cooling system i.e. lake water). Hot 2-cycle engines use an ash based chemistry and the cold 2-cycle engines use an ashless chemistry. The addition of 2-cycle oil as said alone will change the Cold Filter Plugging Point or cloud point of the diesel fuel, and lower cetane - making the vehicle run more suggish.

Today the #2 Diesel fuel we see is in the .825 to .850 API range out of the pump - plain junk - and it is blended to burn cooler for NOx reduction. That gravity range is effectively 40 Cetane. It has terrible ignition delay until the engine warms up and that makes a cold Diesel rattle a LOT. It has poor power qualities. What is written above can raise the API gravity to around .815, and while you do not think that is a lot - you have to consider the API gravity of Gasoline is in the .70 range and below. #1 Diesel might be around .80 - but with lower BTU per gallon - a.k.a. "Kerosene". Yes, #1 Diesel is Kerosene - or actually for road use, ULSK. See http://www.clean-diesel.org/faqs.html

This has little of NOTHING to do with Cetane v Octane as we know of it. It does not apply to a Compression Ignition engine - they RUN by what most people call detonation - or pre-ignition. You WANT the fuel to light off immediately upon hitting the combustion (or pre-combustion) chamber when sprayed out of the injection nozzle - with no delay - whereas in the spark ignition engine you DO NOT want the fuel to ignite UNTIL you light the spark. Cetane and Octane are inverse scales - but in this case irrelevant - lowering the API gravity raises the Cetane rating - and you can do it with a lighter solvent distillate - they WILL mix and not separate. They are BOTH petroleum refining by products.

WHAT IS THE PROBLEM THEN ??

Older mechanics - just like what is stated above - will tell you if you put one gallon regular gas to a diesel tankful after about every four tanks that it would perform essentially the same job as a fuel injector cleaner at a fraction of the cost, or more properly a "tankful" is to add one gallon of gasoline to 20 gallons of diesel fuel as a cheap easy anti-gel for winter fuel. Without adding a lubricity enhancer with today's ULSD fuel - you are risking damage, even in small dosages.

So . . . well then . . . not so fast on that one . . . too much Gasoline really lowers lubricity, and heats up the exhaust gas - because the mixture will burn hotter. Lower lubricity will cause wear on the injectors as they will get hotter from the friction created by the fuel coming through them at higher pressures and lower lubricity, and while hotter exhaust is good to spin a turbo up faster - it can also get it red hot under load faster. You need an EGT gauge to see what is really going on - it soars to over 1,200 F really fast - and that will destroy the turbo and damage then the entire combustion chamber, blow a head gasket maybe and even melt pistons if it goes on too long For guys who have rigged their turbos for higher boost - you risk blowing head gaskets - in addition to higher EGT's from higher boost. Ford Powerstrokes which had the early variable turbo vanes stick open - on regular diesel fuel - the boost would sky rocket literrally to 30 to 50 psi and blew the heads loose and snapped head bolts. That is the power of compression ignition power

You see gasoline and alcohols hit diesel fuel right where it hurts the most. Those light thin fuels will raise the cetane number but - again - and it cannot be said enough - lower the lubricity. To explain how octane and cetane DO NOT work together, it is fact that the light distillates that gasoline is made from have a natural high-octane index. The middle distillates that diesel fuels come from have a high cetane index. The octane and cetane indexes are INVERSE scales that center around the issue of "flash point". A fuel that has a high octane number has a low cetane number because its flash point - and auto ignition temperature is HIGH - that is it resists self igniting on its own, and conversely a high cetane fuel has a low octane number because it readily ignites at a lower temperature or slight under pressure. But an interesting chemical change occurs when the two are mixed together - the high octane fuel - basically is a low flash point solvent - lowers the flash point of the diesel fuel - and thus raises the cetane. This is would be good IF and ONLY if it raised the lubricity too. This is where the issues of it being a good anti-gel and fuel system cleaner come into play.

There are lots of people who have a backwards understanding of this and you can find it written in articles all over the Internet. It is what they "think" and not chemistry - they usually do not understand.

Gasoline will raise the combustion temperature. This might or might not help reduce carbon deposits in the cylinder. The hotter combustion temperature will not hurt the injection nozzle - but the increase in heat caused by the increased friction of the dryer - lower lubricity fuel under high pressure going through it WILL. It will dissolve other heavier Hydrocarbon deposits in the nozzle and push them through - effectively cleaning hte injector; however the fuel being injected is the only thing that cools the nozzle.

Diesel fuel has a lower combustion temperature than gasoline. The fuel injectors also depend somewhat on the fuel burning at the correct rate and temperature for a long life, but lack of lubricity will kil them before heat will. However,. If the combustion temperature is raised long enough, the gums and varnishes in straight gasoline WILL start to cook right in the fuel injector and turn into carbon. Then these microscopic carbon particles will abrade the nozzle. High combustion temperatures alone will shorten fuel injector life, and straight gasoline in high quantifies makes the problem worse, BUT we are not talking about STRAIGHT gasoline.

Gasoline and alcohols do have an anti-gel effect on diesel fuel, but these fuels if used alone are too thin and will hurt the lubricity. Alcohols work as a water dispersant in small amounts, but also attract water in large amounts. Alcohol unlike Gasoline as a petroleum distillate does not blend into Diesel fuel well. Diesel fuel is already hydrophilic (attracts water) so why add to the problem. The old timers got away with this because high sulfur diesel fuel had enough lubricity to take some thinning. Today low sulfur diesel fuels have barely adequate lubricity, so you would not put anything in the tank that would thin out the fuel more, reduce lubricity, or attract water.

Cetane is to diesel fuel what octane is to gasoline. It is a measure of the fuels ignition quality - in short its ignition delay as a measure of ignition performance. Cetane is actually a hydrocarbon chain, its real name is 1-hexadecane. It is written as C16H34, or a chain of 16 carbon atoms with 34 hydrogen atoms attached. All pure HC chains are also referred to as paraffins - more properly called "alkanes". Cetane is a hydrocarbon molecule that ignites very easily under compression, so it was assigned a rating of 100. All the hydrocarbons in diesel fuel are indexed to cetane as to how well they ignite under compression. There is very little actual Cetane in diesel fuel.

More properly, in organic chemistry, an alkane, or paraffin (a historical name that also has other meanings), is a saturated hydrocarbon. Alkanes consist only of hydrogen and carbon atoms and all bonds are single bonds. Alkanes (technically, always acyclic) have the general chemical formula CnH2n+2. Alkanes belong to a homologous series of organic compounds in which the members differ by a molecular mass of 14.03u (mass of a methanediyl group, —CH2—, one carbon atom of mass 12.01u, and two hydrogen atoms of mass 1.01u each). There are two main commercial sources: crude oil and natural gas, therefore an "alkane" can be either liquid, solid or gaseous.

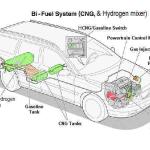

All the hydrocarbons in diesel fuel have similar ignition characteristics as cetane. Cetane is abbreviated as CN. A very loose way to think about cetane is if the fuel has a CN of 45, then the fuel will ignite 45% as well as 100% cetane. Diesel engines run just fine with a CN between 45 to 50. There is no performance or emission advantage to keep raising the CN past 50 because it is ONLY a measure of how fast it ignites when injected. After that point the fuel's performance hits a plateau unless there is more BTU to be burned. For instance - if there is another fuel also present being ignited - like CNG - then the faster, and hotter, ignition has value - because CNG needs about 1,500 F to ignite well and fast. There - then - is more horsepower - but not from the Diesel fuel - from the CNG. For instance the speed of ignition in a bi-fueled Diesel is related to how fast it can ignite the other fuel in the combustion chamber - say CNG or Hydrogen. In this case the Diesel fuel is acting a a liquid spark plug - and so you WANT a fast and hot ignition. In other words - very SHORT ignition delay for maximum power on the stroke.

Diesel at the pump can be found in two CN ranges: 40-46 for regular diesel, and 45-50 for premium. The minimum CN at the pump is supposed to be 45. The legal minimum cetane rating for #1 and #2 diesel is 40. Today with ULSD is it barely 40 most places. Most diesel fuel leaves the refinery with a CN of around 42. The CN rating depends on the crude oil the fuel was refined from and the distillation temperature they draw it off at. It varies so much from tanker to tanker that a consistent CN rating is almost impossible. Then if that tanker had Gasoline in the previous delivery - it will change upon filling into that tanker. Distilling diesel is a crude process compared with making gasoline. Gasoline is more of a manufactured product with tighter standards so the octane rating is very consistent. But, the CN rating at the diesel pump can be anywhere from 38-46. That is why there is almost never a sticker on a diesel fuel pump for CN.

Premium diesel is supposed to have additives to improve CN and lubricity, detergents to clean the fuel injectors and minimize carbon deposits, water dispersant, and other additives depending on geographical and seasonal needs. More biocides added in the south in summer, more ant-gel added in the north in winter. Many retailers who sell premium diesel will have little brochures called (Point of Purchase) at the counter explaining what is in their fuel. Good luck with that today or it being accurate and truthful. A Diesel engine will run on ANY Hydro-Carbon - gaseous or liquid. Heck the first Diesel ran on powdered coal and compressed air. How well it will run is the issue, and how much power it will develop at a given RPM is the matter-of-fact to be concerned with.

Because there are no legal standards for diesel beyond it being no more than 15 ppm of sulfur as now mandated ULSD in America -, it is very hard to know if you are buying good fuel. Enforcement of all fuel standards is done at the state level in the USA and in reality it is not checked - or very loosely checked. It could be anything - as a Diesel engine WILL run on pretty much anything that will explode in a compression engine - except not to risk a huge fine - it will always be ULSD - as mandated by law and nothing more as a standard. Since Hydrodesulfurization (HDS) as a catalytic chemical process widely used to remove sulfur (S) from natural gas and from refined petroleum products such as gasoline or petrol, jet fuel, kerosene, diesel fuel, and fuel oils.ALSO strips some of the BTU per gallon and the lubricity - it is supposed to be replaced with additives - but good luck with that today.

The legal requirement to remove the Sulfur is ALL the refinery is required by law to do - and to put in additives for lubricity and BTU content is NOT mandated by law - AND -will add to the price of the product at the pump, and require they RE-CHECK they are still complying with the ULSD standard mandate. The purpose of removing the sulfur is to reduce the sulfur dioxide (SO2) emissions that result from using those fuels in automotive vehicles, aircraft, railroad locomotives, ships, gas or oil burning power plants, residential and industrial furnaces, and other forms of fuel combustion. So what you end up with is a cooler burring, low cetane, lower BTU, and lower lubricity fuel. All BAD realities you as a consumer cannot check on your own. A cooler burning Diesel fuel barely will spin a Turbocharger well. Diesel fuel is an international commodity for industry. Therefore, you should be picky about where you fill up. Shop for price from a large volume retailer so you have the freshest fuel. That is about the best advice anyone can give. then if you are smart - you will have a Hydrometer and check the gravity of the fuel - and if smarter still - add lubricity and lower the the flash point as described above.

The 1994 legislation and reformulation of diesel fuel in North America is due to an international effort for lower emissions. Cleaner diesel emission laws are here. 2009 and up heavy duty engines in America mostly now use Diesel Exhaust Fluid (DEF) - a 30% urine concentration sprayed onto an exhaust catalyst to further reduce emissions. Diesel fuel is now being reformulated into a cleaner fuel in general. Without getting too technical (this is over-simplified and very generalized), diesel fuel for the most part is made up of two different hydrocarbon families: paraffins and aromatics. The paraffins have a naturally high cetane index, burn clean, but cause the annoying gel problem in winter. The aromatics have a naturally high lubricity, low cetane index, and cause a lot of diesel emissions and soot. Reformulated diesel will have a higher paraffin content, higher cetane number, and a much lower aromatic and sulfur content. It will also be more prone to jelling and have a lower lubricity.

THE PROBLEM THEN IS THE INTERNET ITSELF

You see a lot of people and posts on the Internet trying to explain Diesel fuel and engine issues by Cetane vs Octane and distillate data - and the plain truth is a diesel will run on almost ANY fuel - and yes Gasoline included. In short they do not know what they are talking about - but they just HAVE to type something for someone other idiot to accept as gospel. The plain facts and scientific truth about diesel fuel is written below. A Diesel engine runs excellent on pre-turbo water / methanol injection and CNG or HCNG - or straight Hydrogen gas. Water injection both cools the inter cooler system and the intake air temperatures of the engine and acts as a pyrolysis fueling source of Hydrogen.

In 2009 a team of gearheads at the University of Wisconsin-Madison have developed an engine that could handle a blend of gasoline and diesel fuel. It outputs low emissions, and offered up to 20 percent greater fuel efficiency. The fuel injection system, was called "Fast Response Fuel Blending," and it mixes the fuels in the combustion chamber to precise proportions. Because the control is so precise, the engine runs at a lower temperature, which means less heat-related energy loss. Also, because the fuel mix is carefully optimized, there's less wasted fuel in the combustion process. The proportions adjust on the fly according to real-time situations a vehicle faces. Depending on how much weight a truck is carrying and work an engine is putting in, you might see the gasoline-to-diesel ratio vary from 85:15 to 50:50--it really just depends.

You could blend two stroke oil 50 - 50 to gasoline and one ounce per gallon would "probably" be safe - but you could blend two stroke oil 85 - 15 to gasoline and absolutely be safe - at 1 ounce per gallon of fuel in the tank - but again which one depends on the fuel you buy from where you are located.

What this is saying in layman's terms is this is a bi-fueled diesel engine and the lower flash point higher ignition heat temperature of Gasoline acts as a catalyst to help the Diesel fuel light off fast and yet cooler - so NOx does not really form - and the best BTU off the fueling process is realized. The Gasoline acts as a "liquid spark plug" for the diesel fuel - rather than just combustion heat and compression heat pressure alone to light the Diesel fuel. In short the effective ignition delay of Diesel fuel - is shortened by the rapid flash firing of the Gasoline. Does the same thing happen if the Diesel is mixed with Gasoline ??? Yes - but without adding something to increase lubricity - the friction of the dryer Gasoline as a fuel will destroy the INJECTION system - and at some points it - as a general fuel will burn so hot as to both increase NOx formation and raise exhaust gas and combustion temperatures to dangerous levels.

So you see, groups at the University of Wisconsin and Lund University tested gasoline fuels in diesel engines, as a Diesel engine WILL burn anything. They demonstrated high-load capability using gasoline and ethanol in both heavy-duty and light-duty diesel engines. Extensive computational studies were conducted by others that predicted cylinder pressure, heat release, and emissions for gasoline injection were compared to those for diesel injection. Both single and double injection strategies with various injection timings were investigated to achieve minimum emissions. With this previous work, it is evident that operation of CI engines on gasoline fuels can greatly facilitate low NOx and low smoke operation. See this link => http://www.skyfi3.delphi.com/pdf/techpapers/2011-01-1386.pdf

Fueling systems is our business and we tell you the truth. the best way to bi-fuel a diesel is with a gaseous, cooler exhaust fuel - like pure Hydrogen made on the fly. If it is made on the fly - you are making your own fuel for "free", and your effective Miles-Per-Gallon go up - or actually "operating costs per mile" go down - because the true power source of the engine is the secondary "fumigated" metered fuel.

A common cause of poor engine performance is the use of low-quality diesel fuel in equipment. The properties of diesel fuel, proper fuel quality checks and finally, storage maintenance checks are critical to ensure operators are using quality fuel.

“The important thing to remember is that diesel fuel quality deteriorates every time it is handled,” Of course, diesel begins its life in the oil well before traveling to a refinery. It’s then transported to a terminal through a pipeline.

“But what was in that pipeline previously?” . “And remember, a terminal sees multiple receipts of diesel fuel that your fuel has come into contact with.” From the terminal, the diesel is handed over to a fuel jobber, “someone you trust in to bring the proper fuel you’ve ordered,”. The jobber fills a tank that has likely been used to transport other fuels before delivering it to you and your storage tank.

“Always be cognizant of the fact that by the time it goes into your equipment that fuel has been transferred seven to eight different times,”

Properties

Several important properties of diesel fuel affect its usefulness. Operators can gain a better understanding of fuel quality by sending samples of diesel fuel for testing in a laboratory to find these measurements.

Heat Value – This is the amount of energy stored in one gallon of diesel fuel. It is measured in BTUs and indicates how well the engine converts the heat energy of combustion into actual work. The higher the heat value per gallon of fuel, the more power that will be derived from each gallon of fuel used.

Cetane Index – Typically diesel fuels have a cetane number between 40 and 55. A cetane rating of 40 or above is currently the standard for all on-highway diesel engines. A higher cetane number is beneficial during engine starting and warm-up as well as in cold weather and in service with prolonged low engine loads.

API Gravity – This measurement determines fuel density and, along with Distillation (defined below), is used to calculate the Cetane Index. Diesel fuel normally ranges from 20-45 API Gravity. Another name for this measurement is specific gravity which refers to the ratio of the density of the fuel versus the density of water. Specific gravity can be measured with a common hydrometer and ranges in diesel fuels from 0.8 to 0.94. (Lower is better - Gasoline is around .70)

Flash Point – This is the temperature where the vapors that form above the surface of a liquid fuel will ignite when exposed to an open flame. The minimum Flash Point of diesel is 125 degrees Fahrenheit . Flash Point has a minimal effect on engine performance and more so informs the proper handling and storage of the fuel. Flash Point allows operators to check fuel quality because it indicates if the fuel has come into contact with any lower-quality fuels.

Viscosity- The measurement of a fuel’s resistance to flow at a given temperature. Diesel Viscosity typically falls within a range of 2.4 to 4.1 cSt. When Viscosity is outside of this range, fuel injector performance may be affected. Diesel fuel can be too thin or too thick for proper engine operation, so viscosity is a critical property in blending diesel fuel.

Distillation- Measures the initial boiling point and separation of distillates at different temperatures and identifies dangerous or damaging gasoline contamination to diesel fuel. Diesel fuel volatility is represented by a 90 percent Distillation temperature which is the temperature at which 90 percent of the diesel fuel is distilled off with an acceptable range of 282-338 degrees Celsius.

Sulfur Content (parts per million) – To minimize potential problems and reduce exhaust emissions, Environmental Protection Agency regulations require a Sulfur Content no greater than 15 parts per million in highway diesel fuels. However, lowering the sulfur content of diesel fuels reduces its lubricity, its ability to lubricate moving parts, especially those in the fuel injection pump and injectors. Most fuel providers have added a lubricity additive into the blend and there are aftermarket lubricity enhancer available. Fuels with lubricity additives are more expensive.

Cold Weather Analysis

These are some worthwhile properties to remember and tests to run when the cold season comes.

Cloud Point – Diesel fuels contain paraffin wax and in cold temperatures the wax begins to congeal and solid wax crystals can form in the fuel which plug fuel lines and engine filters. Cloud point is the temperature at which these crystals of paraffin wax begin to appear in the fuel. You can actually detect the presence of these wax crystals by a cloudy look to the fuel.

Pour Point – If the temperature continues to drop below the Cloud Point, the fuel will reach and exceed its Pour Point, becoming too thick to flow and eventually becoming a solid. Pour Point determines the temperature at which this happens. There are additives available which can improve fuel flow and lower the Pour Point in extremely cold temperatures.

Cold Filter Plugging Point – Measures the temperature at which wax crystals form in a fuel to the extent that they plug filters.

Contamination

Below however in detail is various types of fuel contamination. “This will be one of your biggest pains in your rear end,”.

Water and Sediment – Both can clog fuel filters and cause significant power loss, corrosion, fuel system component wear and promote microbiological growth. The amount of water in fuel should not exceed 500 ppm or .05 percent. Sediment should be no greater than 100 ppm, or .01 percent.

Bacteria, fungi and mold – The presence of bacteria, fungi and mold indicates that fuel storage tanks have not been properly maintained. When present, water separates from fuel and accumulates at the bottom of storage tanks creating an excellent breeding ground for biological growth. Initially, diesel fuel is sterilized thanks to the high temperatures involved in refinery processing, but fuel can quickly become contaminated with microorganisms present in air or water that contain bacteria and fungi.

Maintenance tips

With all of this information in mind, keep in mind several maintenance tips to ensure these problems don’t slow you down. First, ensure that you purchase fuel from a reputable supplier. To do so, ask the supplier to provide a certificate of prior analysis for each shipment. This should cover sulfur content, color (dye) if any and assurances regarding the transport vehicle, whether or not their tank was cleaned of other products before storage or transport. If it is a common gas station look for one that vends a lot of diesel. That means they will more likely have fresh fuel always.

Inspect each delivery you receive using a diesel Hydrometer at the least - like a Kent-Moore J-38641-D or C or B Diesel Fuel Hydrometer and each fuel compartment of the shipment to ensure it meets the certificate of analysis and is free of excess water and sediment if you can. If you are buying a big load in bulk for farm, industrial or other use, afterward, it is a good idea to take a sample of the shipment and send it to a lab for testing. here is one => http://www.kmtlabs.com/Analysis/D240_BTU.aspx

When it comes to storing your diesel, inspecting storage tanks and fuel systems at least once monthly. Drain water from the tank(s) as needed, which helps to prevent microbial contamination. Keep tank(s) as full of fuel as possible in order to reduce the volume of outside air from entering. This reduces moisture as the air condenses. Finally, install desiccant air breathers to reduce moisture and sediment from entering the fuel system, and use microbial treatments and dispersants for the killed growth.

Similar to the octane number seen on a retail gasoline dispenser, a cetane number rates a diesel fuel’s quality of ignition. But that’s where the similarities end. The octane number of a gasoline measures its ability to resist auto ignition commonly referred to as pre-ignition, knocking or pinging. A diesel fuel’s cetane number, however, is actually a measure of the fuel’s ignition delay; the time period between the start of the injection of the fuel and the start of the combustion of the fuel (commonly known as ignition). In general, a higher cetane fuel will have a shorter ignition delay period than a lower cetane fuel.

Since diesels rely on compression heat for ignition, the fuel must be able to readily auto ignite and quicker is better. A higher cetane number indicating a shorter ignition delay time usually means more complete combustion of the fuel. This translates into Quicker starting, Quieter operation with less diesel chatter, Improved fuel efficiency, a reduction of harmful emissions, less wear and tear on the starter and batteries, and Quicker pumping of protective lubricating fluids throughout the engine system.

There are basically only two ways to gain a higher cetane number. The first is to do it during the refining process. Refining a high cetane diesel fuel usually results in a fuel with a higher API gravity rating and a lower density. A low density fuel contains fewer BTUs and consequently provides less power to a diesel engine. A typical gravity for #2 diesel fuel is in the 32-

34 range compared to a high-cetane fuel which typically has a gravity rating in the 36-38 range and more closely resembles a #1 diesel fuel. BUT . . .when a higher cetane number is gained through the refining process, it usually means the fuel contains fewer BTUs, resulting in less horsepower and poorer fuel economy. In other words #1 diesel starts easy and burns cleaner but has less power than #2. You will thus find lots of #1 diesel in cold weather climates - it is also called Kerosene and #1 Heating Oil..

Another way to gain a higher cetane number is through the addition of cetane improver chemistry. BUT . . . when cetane improver is added to a #2 diesel fuel, the result is a high-cetane number fuel with more power and fuel efficiency than a similar fuel derived through the refining process. So . . . Cetane and BTU per gallon are NOT hand in hand.

A side benefit is that #2 fuels usually cost less, too. Cetane numbers can only be measured by a laboratory engine test. Usual methods, such as using a cetane index (a calculation using API gravity and the distillation mid-point) cannot measure cetane numbers accurately when using cetane improvers. Another way to say this is if you mix it yourself - you can only gauge your success by if you can can feel it - but you cannot accurately not measure it.

So . . . the best way to increase "mixed Cetane" is by adding a lower gravity API fuel. Kerosene - also known as "#1 Diesel", is around .80 API gravity; however it also has lower BTU content per gallon - it lights off easier - and has a lower wax index, (cloud, pour and cold filter plugging points) - so . . . but . . . what you want is to lower the API gravity AND raise the combustion temperature slightly, as this will allow you to use water injection most effectively. People call it the "steam effect" but that is no what is going on at all - what is really going on is pyrolysis of the water - and it occurs around 1,000 degrees C - and lower under pressure of the compression engine with a hot enough combustion temperature of the fuel.

So let us close this article with this post => "1% gasoline added to diesel to prevent gelling? Ever heard of this? My relatives use this on all their tractors / offroad equipment as well as their semi's and claim to never have any trouble with gelling. They have been doing it for about 4 years after they read in a service manual for Caterpillar to do this when cold out to prevent gelling. I believe they also add 2 stroke oil to help with lubricity. " This is from =>> http://www.turbodieselregister.com/threads/177491-1-gasoline-added-to-diesel-to-prevent-gelling and you should be able to read the entire post thread - where last we saw - no one was able to answer his question correctly and scientifically

The poster wrote "I personally don't think it is a good idea, I'm just looking for technical reasons why it shouldn't be done. So I can educate them" AND then => "Is it possible that it is okay on mechanically injected diesels vs. a 2nd gen truck with a VP44?"

So given what you just read . . . what do YOU now think ??? We say he - like so many - thinks BACKWARDS for so many reasons he does not understand

This is why you will find mixed mode speak on #1 and #2 diesel fuel and all other things Diesel, abnd if you want to get high MPG from a Diesel bi-fuel it with a gaseous fuel you can make yourself as you drive.

Some items to accomplish this are available at http://bigbay4bestbuys.com

,

,

,

,  ,

,  ,

,

,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,

,

,  ,

,  ,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,

,

,

,

,  ,

,  ,

,  ,

,  ,

,

,

,  ,

,

,

,  ,

,  ,

,