ANSWER: GM 6.5 diesel dual alternators and the batteries

Dual alternators are a must have for the GM 6.5 or to run a decent sized gas production Hydrogen Generator . The reason is they will return the batteries to as full a charge as possible - FAST - depending on how the alternators are set up and /or the second alternator is needed to handle the load of the Hydrogen Generator. Stock alternators with the internal regulators will not do as good a job as commercial external regulators - and at least one external regulator can control both alternators itself. If you have an RV or work truck with an inverter, dual 240 high amp alternators properly set up on a commercial regulator (Taxi - Limousine - Ambulance - Police - RV) system can easily power a small microwave even at idle without drawing on the batteries - and in fact will continue to charge them

A CS-144 can be upgraded to a 200 amp unit with a new 200-240 amp quad wound stator and DR5180 rectifier with 70 amp diodes and a 2 inch overdrive pulley. An AD244 OEM actual DELCO needs just a DR4402HD-3 rectifier to make it a 240 amp output unit, and DR44 series Chinese made alternators can either have the rear housing changed to a DR3580HD-3 with 80 amp diodes - or you can rebuilt it using 3 NTE 5935 and 3 NTE 5934 new press fit 75 amp 400V Diodes . In both cases you need to de-solder the stator. If with the DR44 family you will need to split the rear case off If you cannot see the stator between the two halves of the alternator it is a 230 or 130 unit and you need to replace those as they are not worth the work and they will overheat.

Why does this matter you ask - well because the 6.5 if not running in top shape can consume a lot of battery reserve trying to get it started, and the stock alternator is not designed to re-charge the batteries - only keep them charged. If the engine goes through an extended cranking cycle - even just more than a few seconds - it depletes the battery reserve from 100 percent FAST.

A properly running 6.5 will start nearly INSTANTLY even in cold weather - and there are a number of factors that will affect this the biggest one being what kind of lift pump you have on it.

The driver will not know how hard the alternator is working unless there is an aftermarket combination voltage / amperage gauge properly installed in the cab. To properly install one the ground from both batteries must go through the shunt that feeds the gauge - which is almost always going to be a digital gauge. It will display how many amps the alternator is pushing into the system - and that means to the batteries. A reading of zero at 14.2 to 14.4 volts means the batteries are as fully charged as the regulator system will allow them to be. A reading close to zero or bouncing in low figures means the batteries are fairly well charged, assuming nothing else is drawing a load like a fan or lights et cetera.

Dual alternators when set up properly will operate the regulators to "follow" each other - meaning they will work in unison to drive the alternators uniformly in parallel - trying to maintain the regulator voltage set point even under load - allowing each alternator to effectively put out half what it would need to if it was the only one - and conversely for a severely discharged battery bank both the alternators will put out their maximum effectively meaning the batteries receive more amps to charge them faster.

Do not be confused - it is amps that charges a battery, but high amps at too low a voltage will not charge the batteries either, and high volts in either condition will damage the battery. Charging a battery is effective a load - a short if you will - on the alternator, and if the alternator is too small and the diodes are not of the right quality, will over heat and a diode or multiple diodes could blow or OPEN, permanently. Then the alternator will not put out DC at all. That is why high amp alternators have high amperage "non-avalanche" diodes in their rectifiers, and why it is good to use a a large well fanned alternator like the CS-144 - which pulls air through from the rear across the rectifier - and the AD-244 which is better that has an open frame and pulls air from the front through it. The AD 244 is better to cool the alternator stator and armature, but the CS-144 is rugged and is an alternator style used in many big rig vehicles simply known as the "GM large case" alternator in the industry. The AD 244 simply isolates the brushes and rectifier outside of the alternator case itself on the rear under a plastic cover easier to get to and change brushes in. The small 130 style is a non-starter - do not use them as over 105 amps they just cannot take the rigors needed/

The type and quality and even age of battery also matters. An AGM battery will take a charge up to about four times as fast as a regular lead acid flooded battery. A pure lead AGM will take a charge as fast as any lead acid battery out there - assuming it is not sulfated. Read more details at battery university

See also https://bigbay4bestbuys.com/The%20AGM%20Battery%20dirty%20secret

There is a nasty demon in the battery equation - "sulfation" - which occurs when a battery is drawn on for power and then not returned to a full charge almost immediately. A lead acid battery produces electricity through a chemical reaction of a "salt" - in this case sulfuric acid and the lead plates. In the reaction the sulfuric acid is returned closer to the gravity of water - and the sulfates collect in crystaline form on the lead plates.

A lead acid battery generates electricity through a double sulfate chemical reaction. Lead and lead dioxide, the active materials on the battery's plates, react with sulfuric acid in the electrolyte to form lead sulfate. ... Sulfation can be avoided if the battery is fully recharged immediately after a discharge cycle.

It has been said trying to charge a sulfated battery is like trying to wash your hands with rubber gloves on.

Charging alone will not get the sulfation back into solution - but pulse charging usually will. Pulse chargers can be expensive and alternators by themselves do not do it - however if you run your vehicle with a "de-sulfator" running at the same time you are running the engine under an electrical load it will "blast" or vibrate loose the sulfate particles and they will in turn return to solution in the aqueous form and raise the gravity of the acid. That is why using a battery hydrometer can be a measure of how well the battery is charged. Running a desulfator over time one can measure the Cold Cranking Amps (CCA) returning up to closer to the advertised level and the battery will crank the engine faster.

But that is not the full story - it is recommended that one procure a digital battery tester - like a Foxwell BT-100 or similar which will actually measure the cold cranking amps - or reserve capacity of the battery. This is effectively also a measure of how "sulfate free" the battery is - and how healthy the plates are. Contrary to popular belief those lead plates in most all batteries except three brands at this writing - are NOT pure solid lead. Only the Odyssey, NorthStar and the Exide - of which models that say they are pure lead - are pure lead batteries. All the Odyssey models at this writing are pure lead. Those few batteries can be desulfated and freshened with acid and if taken care of properly will last for ten years or more.

The rest of the batteries on the market all have composite plate technology. You can read about batteries at Wikipedia , but the point here, is if you desulfate a composite plate that is old or poorly made the plate will actually vibrate the paste on the plates loose and it will end up in the bottom the battery and short it out. the Wiki page claims there is no proof the desulfators work - and the reason is the way and various ways the plates are made of alloy and paste, so there is is identifiable way top prove how a desulfator works - but they do work. An AGM battery will not let the paste fall off so much as it will loose electrical connectivity, and the battery will never return to as high a reserve capacity as it once had - though it will improve over being badly sulfated as the gravity of the acid will rise.

Why this matters to the 6.5 is because - every glow plug cycle - that is every time the key is turned and the "wait to start" light comes on, there is effectively a direct short across the battery, discharging it and slowly eventually causing a sulfation buildup because a short drive and a single alternator will almost always NEVER bring the battery back to full charge again.

Alternators normally only maintain a battery charge

It's a common misconception among drivers that if their battery is flat dead, a good long drive will charge it up. First if it is below 12.3 volts that is considered dead, as in 50 percent of the charge is gone. Most alternators as set up from the manufacturer can revive batteries that have drained somewhat, but they can't revive a dead one with no voltage at - or below 12 volts. In a properly functioning vehicle or engine setup, the battery is there to start the engine and be an electrical load-balancer to bring back and maintain the float charge of the battery . After the initial current draw of the starter motor, the alternator takes over and runs all the loads of the lights, wipers, radios and other electrical items after providing a topping-off charge to the battery. Run that battery down far enough under about 10v and either most alternators via their regulator systems will not recharge it, or it will damage the cells and give them a surface charge that will draw off so fast that it makes the charge useless. Most alternators have a warning label like this on the box when you buy them:

This is why severely depleted batteries take a long time on an alternator to get and hold a charge to the battery if they ever can at all.

if you have to keep charging the battery, it means either your alternator is about to give up and it actually is not putting out enough amps to do its job or you have a heavy load like a big aftermarket stereo - or a hydrogen generator drawing lots of amps , or more likely, the battery itself is about to give up because it is sulfated badly and won;take and hold a charge of a sufficient Cold Cranking Amp level As explained herein depending on the battery construction you have and its age, expect 3 to 4 year's life out of a normal 12v car battery, irrespective of what the manufacturer or guarantee tells you. 5 years is out of the ordinary. 6 years is extreme. An AGM may last longer, and an AGM Deep Cycle longer still to seven years. A pure lead battery may last ten years or more and can be de-sulfated without damage and refilled with fresh strong battery acid to bring it back to near new specs. If you live anywhere with wild temperature swings, expect a shorter life like 2 to 3 years before you need a replacement.

Another ugly secret is that the 244 style alternator from GM is short-sold. It has a quad wound stator which can put out up to 300 amps with the right diodes. The 145 amp version simple has 50 amp diodes so only 150 amps will pass - 50 amps times three is 150. So it you put in 80 amp diodes 80 times three is 240 - a.k.a - the high amp version. If you are our customer and want to do the upgrade -- contact us through your account and we can put up a page with parts for you to to buy to make the conversion based on your alternator model. Another way to do this is to run rectifiers in parallel - in which 6 times 50 amp is 300 amps - or times 80 amp is 480 amps through the stator will not go that high and would likely over heat so bad itr may fail - as in short out or at the least the internal voltage regulators would over heat and fail first.

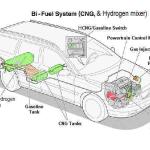

Hence to run Hydrogen Generators one needs to run dual alternators because one alternator is needed to effectively power the Hydrogen Generator load, and they need to be specially manufactured for high amperage output at low speeds

Only a commercial heavy duty charging regulator measures the battery load it is receiving and continues to adjust the alternator output in a more fine grained manner to keep charging the batteries until they detect a low enough resistance that they effectively cut the alternator "off" as to amperage being produced. Then as the battery remains at a state of being fully charged, the commercial regulators wil roll back the alternator voltage output to what is known as "float voltage" to maintain charge without harming or over charging the battery. A battery that is over charged will heat up and can explode - as the electrolyte appear it "boils" it is actually - acting as in electrolysis and is producing Hydrogen gas and it takes very little heat to light it off.

Different types of battery require different charging regimens, so you need to be careful if and in mixing and charging different design batteries. A standard lead/acid battery is charged at up to 14.8 volts; a sealed lead/acid or AGM at 14.4 volts; and a gel battery at 14.1 volts. Today most vehicle charging systems are set at 14.3 volts, and gel batteries are now rare, so AGM batteries work fine now, and lead acid batteries can be charged just fine at 14.3 volts. If you have an older 14.7 charging system, change the regulator to a 14.2 set point. which is the 14.3 style.

The problem still is if you discharge your batteries - even AGM deep cycle batteries a standard regulator on the alternator will never let them return to full charge and they will still sulfate internally. There is a trick called "hard charging" where you can put a dead battery in parallel momentarily - for a period of time to force the alternator regulator to stay closer to 100% duty cycle and keep charging; however a single alternator will overheat and cannot take the load anyway.

If you have never heard of any such thing, a company makes a unit that does just that electronically and is called an "Alternator-to-Battery charger", made by a British company Sterling Marine Products. It places a load on the alternator to pull its voltage down and In effect this tricks it into thinking there is a heavy drain on the system, so the regulator which is left in place works at full current output of the alternator The resulting voltage, though, on a standard alternator is usually not sufficient to charge batteries; so the -"Alternator-to-Battery charger" takes this current and amplifies it to charge at a greater rate than is possible with the standard regulator.

You can see this if you use a battery monitor or combination voltage amperage gauge, say for instance —a pair of deep cycle lead/acid batteries — was at 12.2 volts, about 50 percent discharged. Upon starting the engine, there will be a lag of two minutes or so before the "Alternator-to-Battery charger" measures the discharge and started charging, as indicated by a drop in engine rpm or if you have a computer controlled engine you will hear a load on the engine as the load on the alternator increased. With a standard system usually you will never seen more than 13.8 volts go into the batteries, but the "Alternator-to-Battery charger" will be immediately charging at at higher amperage at a slightly higher voltage close to the set point of the regulator. The system designed for dual battery systems can be used to charge one bank and simply maintain another at a lower float voltage.

The "Alternator-to-Battery charger", made by a British company Sterling Marine Products comes in various sizes to handle 12v or 24v alternators up to 210 amps. You can install the Alternator to Battery charger, using existing cables, in less than an hour, and because the alternator is not modified, there are no warranty issues. Nor does it affect the Electronic Control Units (ECUs) on new engines.

It is just as easy however to use a combination voltage and amperage gauge, and when the amperage charge rate drops to zero - turn on the dead battery and the regulators will turn the alternator charge back on to all the batteries, but you need to know what you are doing and turn it back off to prevent overcharging or if left on after the engine is cut off - even discharging ot he good battery bank. If run with a de-sulfator while charging you will clean and get as best a charge back on the battery as possible.

Then use the Foxwell BT-100 or similar to see what the Cold Cranking Amps are after the battery settles down and on good sound batteries you will see the Battery spec get closer to new each time you run-charge them. If your batteries are cheap initially and / or old - however you could just as well destroy them.

While the de-sulfators do work, the moral of the story is if you have an old battery plain flooded lead acid battery already badly sulfated, you are not likely get it back to good condition, and especially if it is not an AGM - you run actually a greater change of destroying it by vibrating the paste on them to nothing - the paste on them is only pressed over a thin flimsy grid plate of what is often a lead alloy that also will crumble. This happens especially on the "cheaper" batteries which are poorly manufactured in the first place.

It is a little know secret that there are only a handful of actual sizable battery manufactures in the US that brand - or badge batteries for others like Autozone, Sears, etc, however they do have low quality lines internally that use different alloy plates and other factors which cause the battery to be classified as a lower quality battery when coming of the assembly line. Also the length of time it actually sat on the store shelf full of acid - it sits there actually sulfating itself before you even bought it. Buy a Foxwell tester and test the next battery you buy - to see how much life it has already lost on the store shelf.

A stock automotive alternator voltage regulator often drops to float voltage at about 75% charge and will not charge the battery any higher. Over time it is a charging system that kills your battery by just owning it, but you can be sure it is easy on the alternator and usually the battery will certainly never explode unless you short the thing - or have the alternator under constant load like with a stereo that eats amps or a hydrogen generator going that eats amps.

Setting up the alternator as a commercial charging system is not hard in the GM CS-144 and 244 - one simply breaking the stator and field connection - at the brush heading to the internal regulator and adds a wire to each that goes outside of the case. The wire on the regulator side is the "stator" and the one on the brush side is the "field", Then the exciter wire normally to the regulator goes shared to the commercial regulator (it would be the one that is wired to the key on of the start and run) and there is a hot wire from the battery, and the regulator must of course be grounded. One of the easiest ones to get and use is the Ford style F540XHD and if it is opened, one can see it is "potted"; however it has a small adjustment resistor point exposed to turn it up or down. It is set at 14.2 volt - but will go - unaltered as high a 14.4 in a dual alternator configuration.

Certainly one way to combat this is to use more than just two large CCA rated batteries and better yet high CCA rated AGM batteries only, but if you have dual alternators your batteries will return to full charge as fast as possible because they can deliver higher amps to recharge them in a faster time period and it will extend their life

,

,  ,

,  ,

,

,

,  ,

,

,

,

,

,

,

,  ,

,

,

,  ,

,

,

,

,

,  ,

,

,

,  ,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,  ,

,

,

,  ,

,

,

,  ,

,